Slab Master Diamond Wire Saw Tips & Tricks

Cut precious gem material with minimal waste using the Slab Master Diamond Wire Saw. This page is designed to give you additional information and to supply you with tips and tricks. We will continue to add more information here so please continue to visit this page. Cutting just one or two stones will show you how easy to use the Slab Master Diamond Wire Saw is.

- We recommend cutting a stone under a (6) in hardness to begin with. Start with Turquoise, Variscite, Meteorite, etc.

- Tune your ear to listen for the cutting sound of the diamond wire blade. You will hear a hissing to a grinding sound depending on the stone you are cutting. This will get weaker over time as the blades begin to wear and this is your best indicator for when you need to change the blade.

- The correct speed is as fast as the bow will run smoothly, without the linear rail bouncing.

- A linear rail bounce is usually caused by improperly tensioned diamond wires.

- The best methods for attaching a stone is to use a hot melt glue gun or standard dop wax. We have even taped stones using thin strips of duct tape.

- Use hot melt glue sparingly as excess glue grabs the diamond wire blades and slows the cutting process down noticeably. Add weight to finish the cut if it hits the hot melt glue and starts binding the diamond wire blades.

- Hard stones (6+) on the Mohs scale are more of a balancing act as the hardness of these stones can ruin the diamond wire blades if you use too much weight/pressure.

- Hard stones do better using smaller diameter diamond wire blades. Note that smaller diameter wire wears out faster.

- Harder stones are easier to cut with a medium grit verses a coarse grit.

- Tests have shown that coarse grit diamond wire can break the diamond tips easier than the medium grit diamond wire.

- Medium grit diamond wire lasts longer on a harder stone.

- Jade and Tourmaline cut faster than Granite or Quartz due to the fibrous nature of these stones.

- Hard stones usually require a blade change in (2) hours or less. Soft stones may only need a blade change in about 20 hours or so.

Please Click On The Icon Below To Join Our Slab Master Saw Community Forum on Facebook

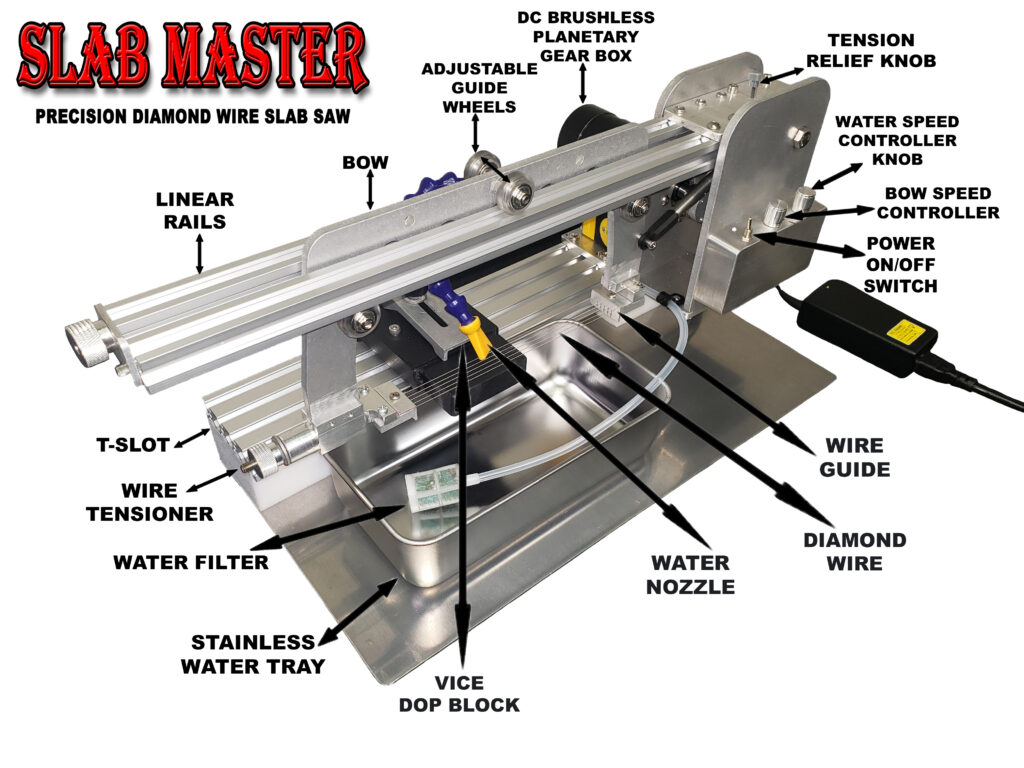

Slab Master Diamond Wire Saw Diagram

Instructional Video For The Slab Master Diamond Wire Saw

Click On The Icon Below To Watch The Diamond Wire Install Video

Click On The Icon Below To Purchase The Slab Master Diamond Wire Saw